Breaking Down the Distillation Process at Our Asheville Distillery

As an Asheville distillery, we take pride in crafting every drop of liquor we produce.

Our American Single Malt Whiskey and Genever Inspired Gin undergo a very intentional distillation process that starts in the grain fields of our Western North Carolina region. Inspired by the legacy of Scottish master distillers, we shape each small batch of our spirits completely from scratch using regionally grown and locally malted barley in Asheville. In an ever-growing field of sourced whiskey, we consider ourselves a true grain-to-glass Asheville distillery and treat each release of our spirit with the utmost care and aforethought.

We start by sourcing Ingredients local to nc

It’s the first step in making our grain-to-glass spirits and sets the tone for the entire process.

We begin with barley, grown & malted in North Carolina. You can taste our commitment to the meticulous sourcing of the spirits we produce. It’s an authentic flavor derived from the fruits of the region, the farming practices used to grow them, and Appalachia’s rich soil.

MALTING BARLEY for our small batch whiskey

The barley undergoes its first transformation at Riverbend Malt House, located in South Asheville, just down the road from the distillery. They carefully steep, germinate, dry, then kiln the barley to develop the desired flavor characteristics.

BREWING (it’s NOT JUST FOR BEER!)

Upon arrival at our Asheville distillery, the malted barley is crushed and mixed with water at very specific temperatures to convert the starch in the grain into sugar. The resulting liquid (or “wort”) is then separated from the grain on its way to the fermenter.

This process builds on the flavor from the malt and care must be taken to not extract too many tannins.

FERMENTATION, FINALLY!

Fermentation is a much-celebrated process responsible for creating alcohol. Most folks think “beer” when they hear the word, but since you cannot make whiskey from anything other than grain and you must ferment grain to make alcohol, it is central to distillation too! Many distilleries skip this process and start with a distilled spirit, but at Oak and Grist, we’re the stewards of this wondrous step.

During fermentation, the sugars present in the malted barley are consumed by yeast and converted into alcohol. It’s a miraculous yet fickle practice that demands stable conditions and close monitoring by our production staff in order to create consistency in the taste and quality of the final product.

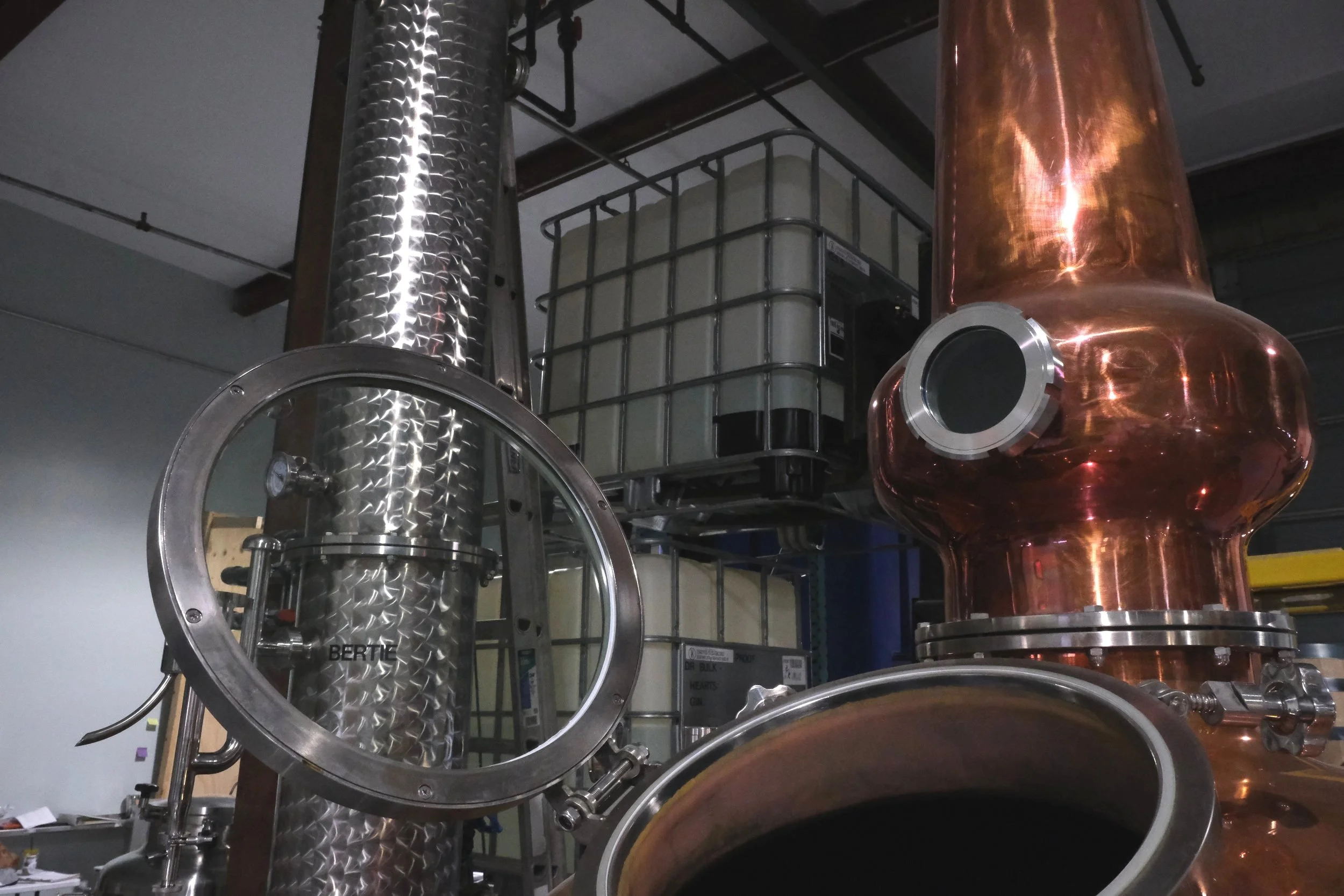

THE PART YOU’VE BEEN WAITING FOR…DISTILLation!

The “distillers beer” is now ready to be boiled, then recondensed through our traditional pot still. We do a double distillation to get our new-make whiskey: first distilling the “beer” into our “low wines”, then distilling the “low wines” into whiskey. Crafting our Genever-Inspired Craft Gin requires an additional third distillation of our whiskey along with eight regional botanicals.

In the simplest terms, distillation is the separation and concentration of alcohol, but during this step, further flavors and aromas are developed.

THE FINAL STEP: AGING our Nc whiskey

It’s the final step in creating our grain-to-glass American Single Malt Whiskey (and sometimes, our Genever-Inspired Gin!). Aging spirits imparts the distinct flavors of the vessel that holds the newly distilled spirit. Here at the distillery, we age our spirit in multiple ways.

Our Single Malt Whiskey, which we hold to Scotland’s stringent standards of a Single Malt Whiskey, is aged solely in used bourbon barrels from a variety of Southern distilleries. When aging our American Malt Whiskey, we choose to age in new American oak barrels, to impart a greater level of character from the char in the cask. Aging time varies depending on the type and style of spirit we are producing.

After the aging process, we hand-bottle & label each and every bottle of spirit that leaves the distillery. How’s that for a hand-crafted touch? Are you as enchanted by the grain-to-glass process as we are? Learn more about our individual spirits or take a guided tour with one of our production team members!